Machine Vision for Medical Device Inspection

Medical Device Inspection

In the medical industry quality standards are as high as they come, and the demand for thorough documentation is stronger than in any other industry. Working with automated quality control in the medical industry requires deep expertise and an understanding of the rules and regulations that govern this industry.

Creating customized inspection systems for medical device production has been a major business area for JLI vision for years, and our advanced vision systems have inspected more than 10 billion medical devices - and counting.

We understand what is at stake for our customers, and we know the ins and outs of the FDA regulations and can ensure that our solutions comply with all relevant standards and requirements.

In this video, Vision Engineer Frederik Thiesson shares how to overcome the challenges of creating machine vision solutions for pharma:

.png)

Why choose a JLI turnkey medical device inspection system?

Validated and developed according to GAMP5 & 21CFR PART 11

We develop, build, and implement advanced machine vision solutions that meet all necessary requirements.

High level of accuracy and consistency

Robust solutions that can detect even the most challenging defects with the same high level of accuracy every time.

Improved profitability

By reducing the ongoing costs of manual inspection, reducing waste, and improving quality you will improve your profitability.

Medical device case study

JLI helped Zeeland Pharma automate a tedious and difficult manual inspection task, and achieve the goal of 99,9% accuracy.

In only 3 months, and on production equipment not designed with machine vision in mind.

Examples of Medical Device Inspection Systems

The Medical Device Inspection Systems are custom-designed turnkey solutions for measuring dimensions, shapes, surface defects, printing, etc.

The systems cover a wide range of product types and production processes. All our equipment is designed for the relevant environment. This means extraordinary reliability, and fail-safe operation and may include high speed and superior accuracy.

Here are some examples:

Tablet Inspection

Tablet dispensers inspection is done in color to ensure that the tablets are placed in the right sequence. The system inspects each tablet and the plastic enclosure for tablet fragments.

Inspection of Catheters

Catheter inspection inspects for finish ensuring that burs and fragments are rejected. Leaving debris in the body of the patient can cause severe complications. Our systems are installed after the end tip is formed just before packaging. By using several cameras or mirrors each catheter is inspected from several angles.

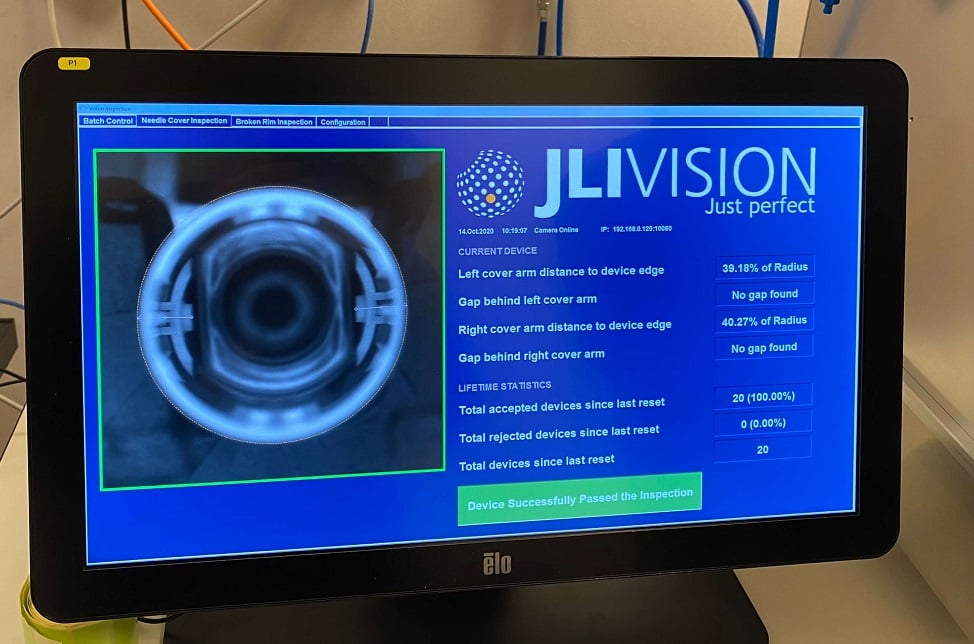

Needle Inspection

When you use machine vision for needle inspection, needle geometry is important to guarantee that the product does not inflict unnecessary pain on the patient. The cutting surfaces must have the right angle and be free of burs. The detection sensitivity is down to a few microns.

Injection systems contain many critical parts. It is essential that all parts are within specifications and assembled correctly. Failure can cause the mechanism to malfunction and thereby giving no medicine or an overdose.

Also, the general appearance is important to show the quality. If the device does not have a perfect appearance it raises questions about the medicine inside.

Mechanics in injection systems must be within tolerances and positioned correctly.

Machine Vision for Medical Device Inspection

The brochure will tell you how vision systems can be used for the inspection of products in the medical industry and go through how you can optimize your QC process by:

- Automating the inspection process

- Streamlining the inspection process

- Improving your product quality

- Detecting defects

Fill out the form and get your Medical Device Inspection brochure. When downloading the brochure, you also sign up for our newsletter.

Example systems in

Medical Device Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

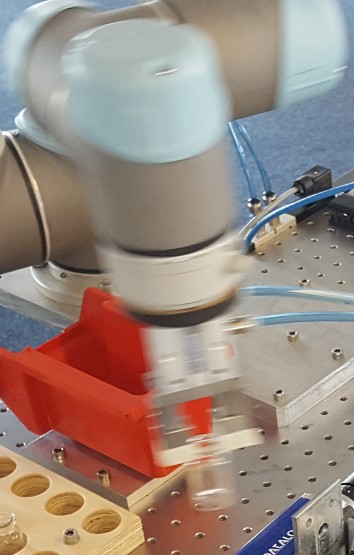

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting