Machine Vision for Packaging Inspection

Packaging Inspection

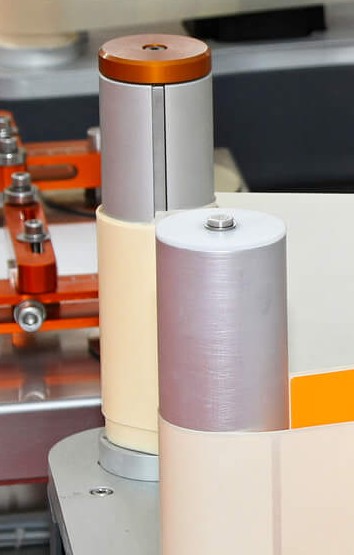

JLI Packaging Inspection Systems are custom-designed turnkey solutions for measuring dimensions, shapes, surface defects, colour printing, and sorting many different products.

The Packaging Inspection Systems cover a wide range of production processes and industries. All equipment is designed for the relevant environment and can withstand the tough conditions at most production facilities. This means extraordinary reliability, and fail-safe operation and may include high speed and superior accuracy.

Examples of packaging inspection systems

We have built vision systems for a wide range of packaging use cases.

This varies from inspecting sealings of plastic packaging for residues, for example in the food industry when packing cold cuts, to inspecting cardboard boxes for dents and defects before they leave the conveyor belt.

When inspecting items related to packaging, having an inspection system that can inspect items at a high speed is often important, as well as the ability to inspect items from multiple sides in a single session.

Why choose the JLI turnkey Packaging Inspection System?

- Adapted to existing production lines

- Internet connection for support

- Excellent reliability track records

- Custom applications

- Validation according to GAMP5 optional

Example systems in

Packaging Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting