Complex color inspection of up to 1.000 items at a time

How we helped Smurfit Westrock automate their quality control with an innovative color inspection system that efficiently inspects up to 1.000 items in one inspection.

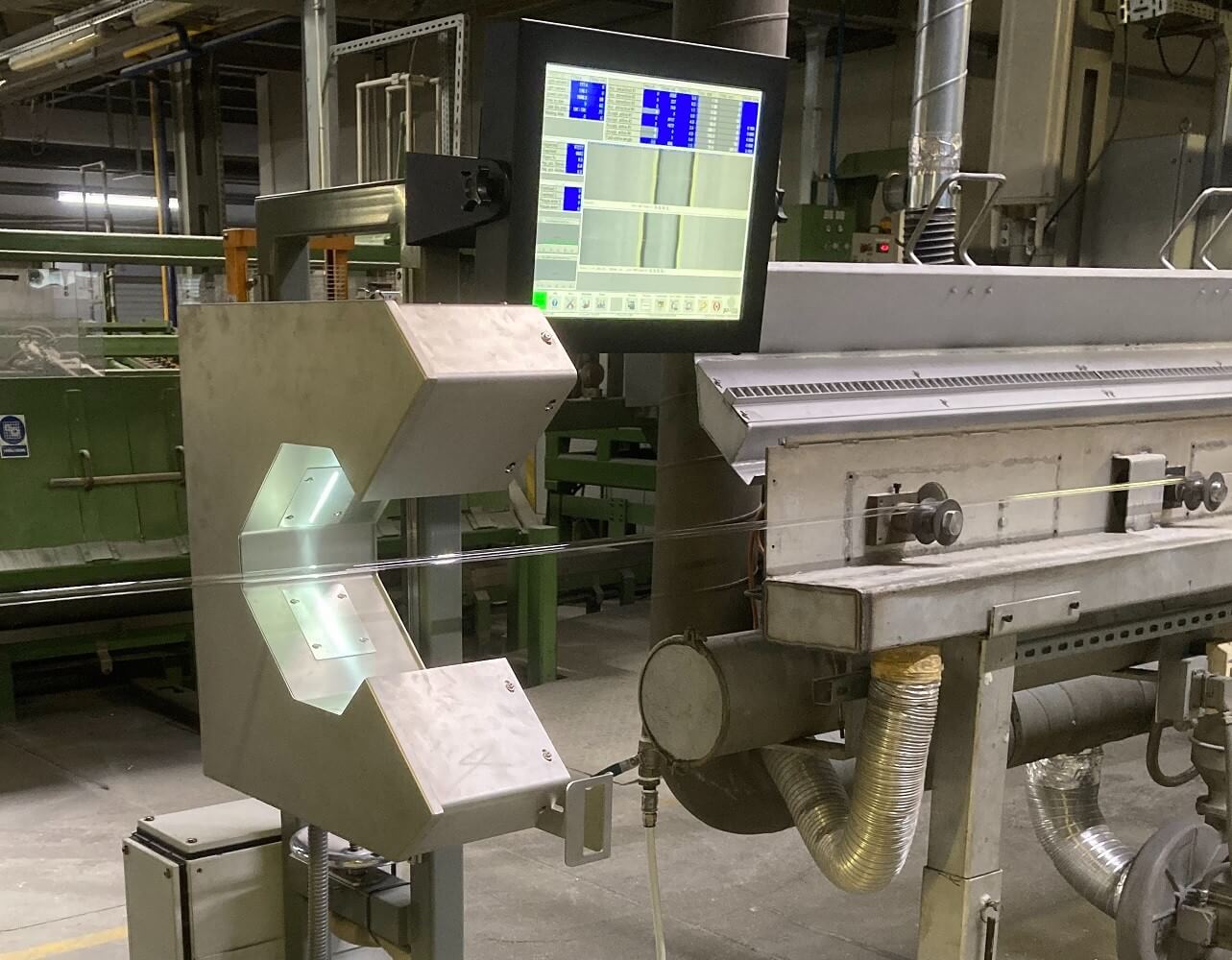

New cost-effective in-line glass tube inspection

Securing and optimizing the inspection of glass tubes for Signify. Changing demands for inspection required a new innovative solution.

3 months to achieve 99.9% accuracy

for inspection of medical devices

How we automated a tedious and difficult

manual inspection task and ensured safety and

quality in the production for Zealand Pharma.

Achieving robustness in changing, harsh conditions

“Using state-of-the-art pattern recognition JLI provided us with a solution that works robustly in a variety of conditions and on top of that is flexible." - Morten Øllgaard Bloach, Project Manager, Qubiqa

98% accuracy in challenging inspection task

Working with a leading manufacturer in the wood industry, we automated the inspection of glulam boards in production lines to eliminate human errors and improve quality.

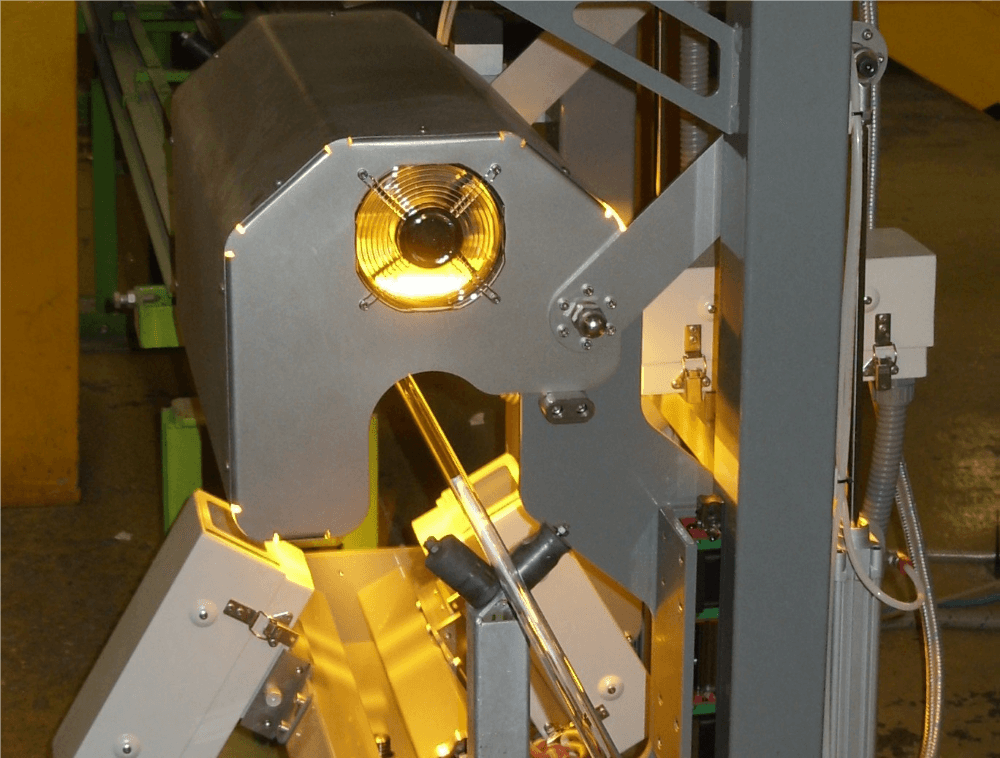

Helping the quartz glass tube industry automate manual inspection

How we automated a challenging inspection task and achieved a classification accuracy that is better and more consistent than the previous manual inspection.

.png?width=1000&height=750&name=Rail%20(Custom).png)

Anomaly Detection on Steel Surfaces

With machine learning, we replaced a labor-intensive manual inspection process of detecting anomalies on steel surfaces.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting