Industrial machine learning

.png)

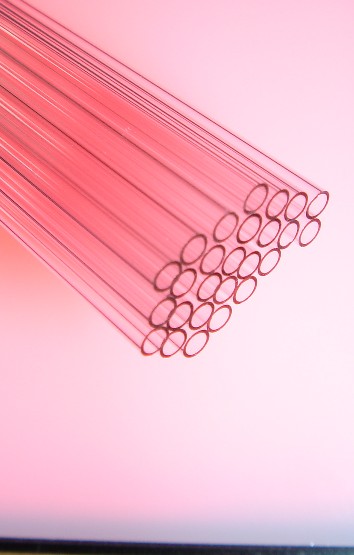

Helping the quartz glass tube industry solve a challenging inspection task

The word “machine learning” is used when a machine imitates "cognitive" functions, often associated with humans. Hybrid vision which JLI has introduced is a combination of:

- Machine learning

- Standard machine vision

- Craftsmanship

Hybrid vision is the perfect solution for the classification of defects. Traditional inspection has been done manually as the production

speed is typically fairly low on quartz tube lines.

Replacing manual inspection with standard machine vision solves some of the problems with manual inspection, but for quartz glass tubes, it is mandatory to distinguish between open and closed airlines. This can be achieved by adding Machine Learning to the standard Machine vision system.

The standard machine vision system is able to detect all airlines and other defects. Images of all detected defects are then fed to the machine learning network that returns a likelihood of the defects being one of the typically 4 different types of defect including open- and closed airline.

The machine learning network is trained by pictures recorded earlier from the standard machine vision system, so the cooperation of the two types of vision helps get the system to perform as specified.

This training can be done in a week or so after installation, as the collection of pictures is automated and only a fraction of the pictures need to be sorted manually before training. Sorting open and closed airlines has so far not been possible to do reliably, but with Hybrid Vision, it is now possible.

Replacing manual inspection with an automated process

Going from manual inspection to an automated system can be a challenge.

One thing is that manual inspection is not always very repeatable, an automated system can be a challenge to set up so it works the same way as the average manual inspector.

The machine learning part helps as the system can be retrained with samples that gradually bring the automated system in alignment with the previous manual inspection, but with both higher accuracy and repeatability.

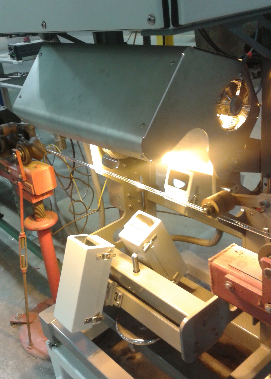

Inspection on the production line

JLI designed, manufactured, and installed an inspection system that inspects quartz glass tubes while the tubes are being transported through the system.

The tubes are scanned and processed using a combination of standard machine vision (selects candidates) and machine learning (classifies candidates).

Classification accuracy is >95% which is better and more consistent than the previous manual inspection.

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)

Download the case study

Can we help you, too?

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting