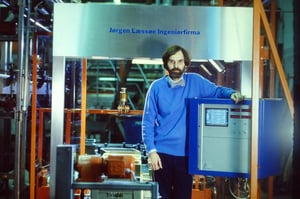

Jørgen Læssøe Ingeniørfirma

"They took a risk on something that had never been doen before, and we took a risk with the company. So we agreed that it had to work at any cost."

- Jørgen Læssøe

This is chapter 2 of the book about JLI vision, "Pushing boundaries".

The potential was huge, but it was still new technology, and while the first project with NKT's nail was a great success, also financially, the following projects did not go quite so smoothly.

For example, the success story from Sanovo was a partial truth at best. In reality, it was difficult to get the system to work well enough, and so many hours were sacrificed on the project that it didn’t turn out to be very good business.

"We took on some tasks that were completely impossible and which have only become possible to solve in recent years with the help of artificial intelligence – including reading handwriting," says Jørgen Læssøe.

With the long wait for profits, Jørgen Andersen's patience ran out. He wanted to shut down the Compu Vision Department and have Jørgen Læssøe do something else.

"I wasn't interested in that, so I decided to start my own business. I could still see that there were fantastic opportunities in it."

From rock musician to entrepreneur

The leap to becoming an entrepreneur was not that big for Jørgen Læssøe. In his younger days, he had lived in England, first making a living playing rock music and then trying his luck in various businesses, with varying degrees of success. These ranged from designing special sound effects for musicians to developing a push-button telephone.

Although the vision industry did not get off to a flying start, Jørgen Læssøe was convinced of the opportunities and did not hesitate to start his own business.

Fortunately, Jørgen Læssøe was not the only one who believed in the future of vision technology, because money was needed to get the new company off the ground.

Palle Kretschmar was an accountant and also a good friend with whom Jørgen Læssøe had lived in a shared house. He helped with the practicalities and even invested DKK 300,000 in the company in exchange for a small share of the ownership. The bank was willing to provide a loan of DKK 500,000, and over the years, Jørgen Læssøe himself had set aside DKK 285,000 in a start-up account, which was now to be used. At the same time, the Danish Growth Fund provided a DKK 780,000 loan, giving the company a strong financial start.

Headhunted by Danfoss

Within the first few weeks, Jørgen Læssøe received a call that almost brought the project to an end before it even got started.

"As I sat by my phone waiting for customers to call, Mercuri Urval suddenly called and asked if I was interested in starting a vision department at Danfoss. I could decide for myself whether it should be located in Aarhus or Copenhagen. I immediately called my accountant and told him that I had been headhunted by Danfoss. He said, ‘But didn’t you want to be self-employed?’. Of course I did, but I was also quite proud to have been headhunted.”

The fact that a financial powerhouse the size of Danfoss was getting into vision was unsettling, but Jørgen Læssøe was convinced that the industry giant was going about it the wrong way.

"They started by laying out the print and building a computer and an image library, cabinets, and everything else that goes with it. They developed programs and even created their own operating system. I started with an existing computer and bought the image storage from Matrox in Canada. I bought what I needed and concentrated on the tasks at hand. That is, creating a proper image and programming a solution."

“Every time a new and better graphics card came out, we bought it, of course. Danfoss had to upgrade by starting with a new circuit board layout and producing a new machine. Something like that takes at least three months. I upgraded my system in a split second, simply by saying yes to the new model from Matrox," Jørgen Læssøe explains.

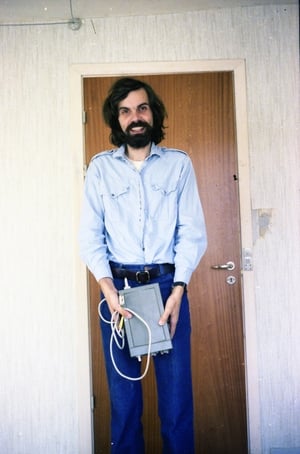

Jørgen Læssøe with the first box inspection system he built for Carlsberg in the 1980s.

Old customers become new customers

Within the first week of starting his own business, Novo Nordisk called to discuss a project that had been in the works while he was at Jørgen Andersen Ingeniørfirma.

"I made sure to say that I couldn't talk to them at all, as I had a one-year non-competition clause, and they asked when it expired. I forgot about the project along the way, but on the day my non-competition clause expired, the phone rang again. It was Novo Nordisk, saying, ‘Well, Jørgen, we can get started now’.”

The project involved checking tablets in a circular tablet package and also included color inspection.

"You don't see that very often. We've probably made a dozen or so color inspection systems in the company's history, so it was a bit overwhelming at first, but we ended up with a good system," says Jørgen Læssøe.

The last shot

However, the company's start-up was not without its problems, and Jørgen Læssøe Ingeniørfirma lost money on its first projects. It was expensive to purchase hardware and time-consuming to turn the concepts into something that worked on a production line.

With just DKK 40,000 left, Jørgen Læssøe decided to invest in having Claus Deleuran create a comic strip that could be used for marketing, and with that under his arm, he spent the last of his money on a stand at an exhibition in the Bella Center.

Claus Deleuran's drawing, which Jørgen Læssøe used at the exhibition in the Bella Center to illustrate how a vision system can help throughout an entire production process, now adorns the wall of the lounge at JLI vision's office in Herlev.

Carlsberg visited the booth and could see how a vision system could potentially solve one of their challenges.

"They had the problem that when they didn't sort the incoming crates properly, Tuborg bottles ended up in Carlsberg crates. That's not acceptable! So that's one of the things I want to be remembered for: that I made sure Tuborg didn't end up in Carlsberg crates and vice versa."

However, it took the brewery manager's persistent effort to get the purchasing department to accept the small start-up engineering company as a supplier.

"The purchasing department didn't think it was a good idea to use a start-up company. But as he said, 'There's no one else who can do it'. So he insisted and was allowed to buy a system, and it worked. And over time, they've bought around 20 systems," says Jørgen Læssøe.

All the way from Stevns in third gear

Perhaps it was quite fortunate that the purchasing department wasn't watching when Jørgen Læssøe began putting the system together.

"I was completely unfamiliar with building systems that way, but I knew we needed a portal over the conveyor belt and how high it should be. But I also had to transport the columns home in my Ford Sierra, so we shortened them a bit to fit in the car. But when I went to pick them up in Stevns, where I had them made, I hadn't considered that they would have to be placed between the front seats. They blocked the gear stick, so I couldn't get the car into anything other than 1st and 3rd gear, and had to drive all the way home from Stevns in 3rd gear.

The brewery manager couldn’t stop laughing when I arrived. We had a really good relationship. They took a risk on something that had never been done before, and we took a risk with the company. So we agreed that it had to work at all costs."

“One of the things I would like to be remembered for is ensuring that Carlsberg did not end up in Tuborg crates and vice versa,” says Jørgen Læssøe.

Read chapter 3: The pioneers in the ragtag company

Or return to the table of contents.