Fast and flexible inspection of injection pen cartridges

Automate inline inspection of injection pen cartridges with a validated AI-based vision system

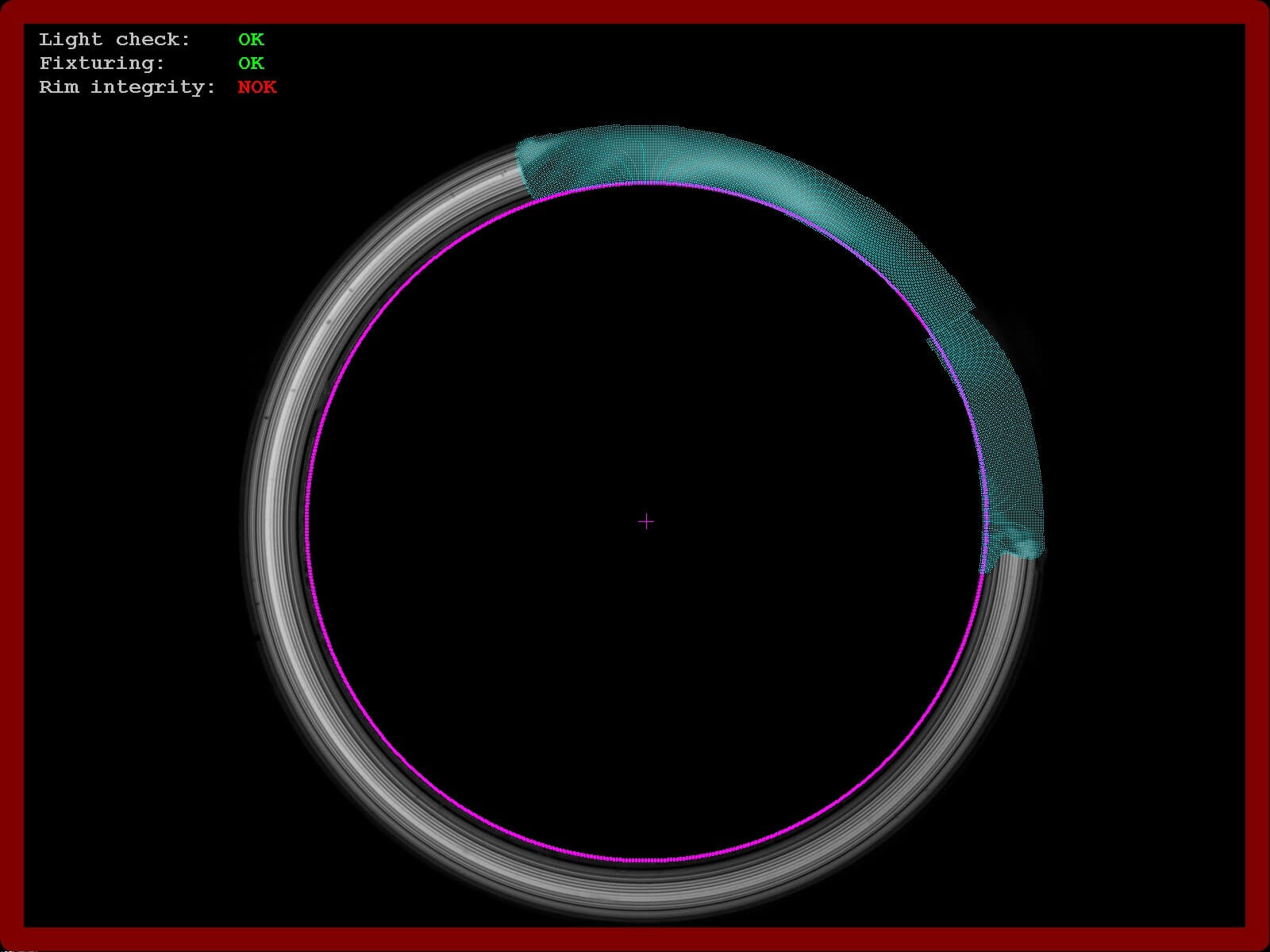

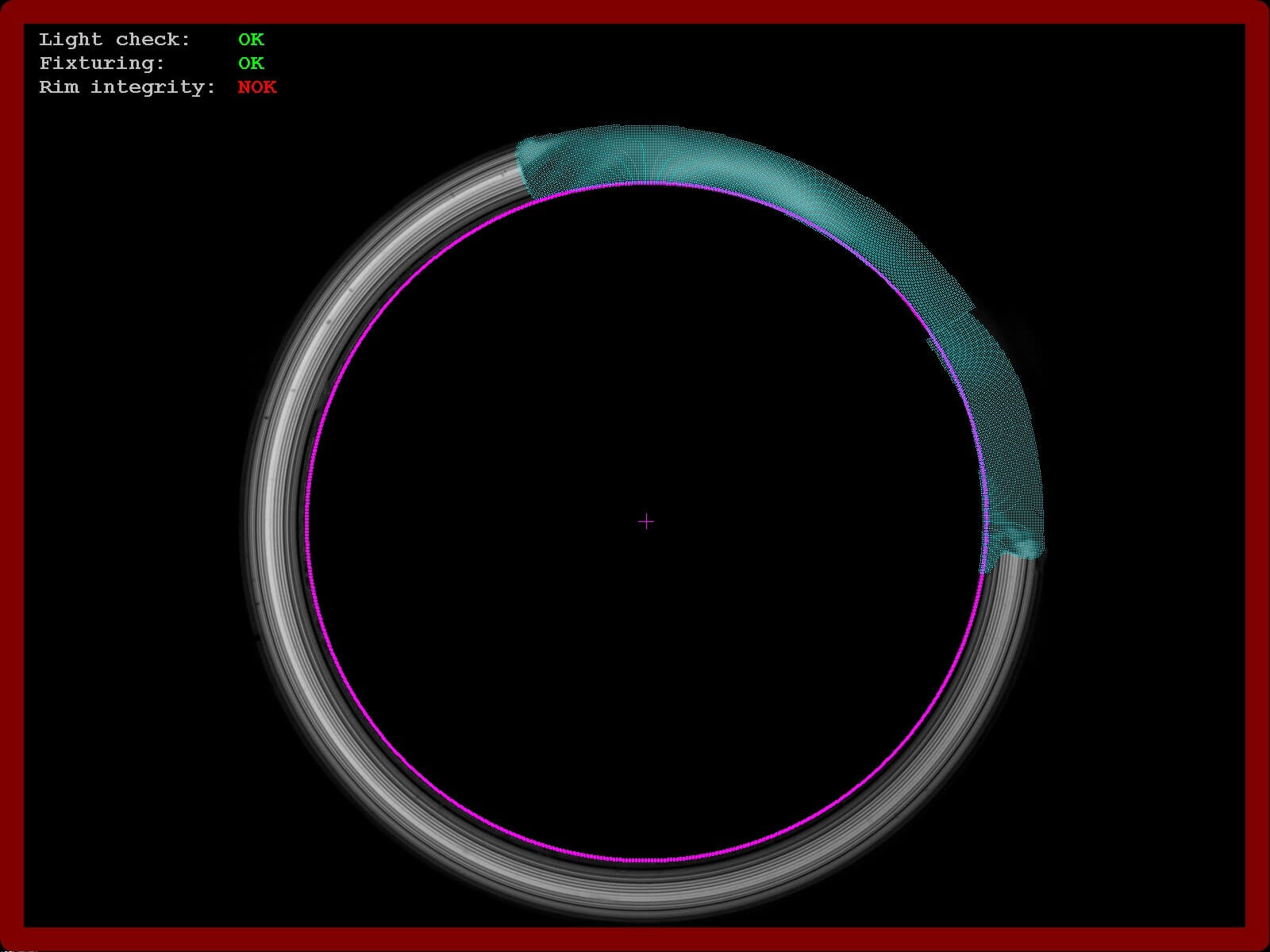

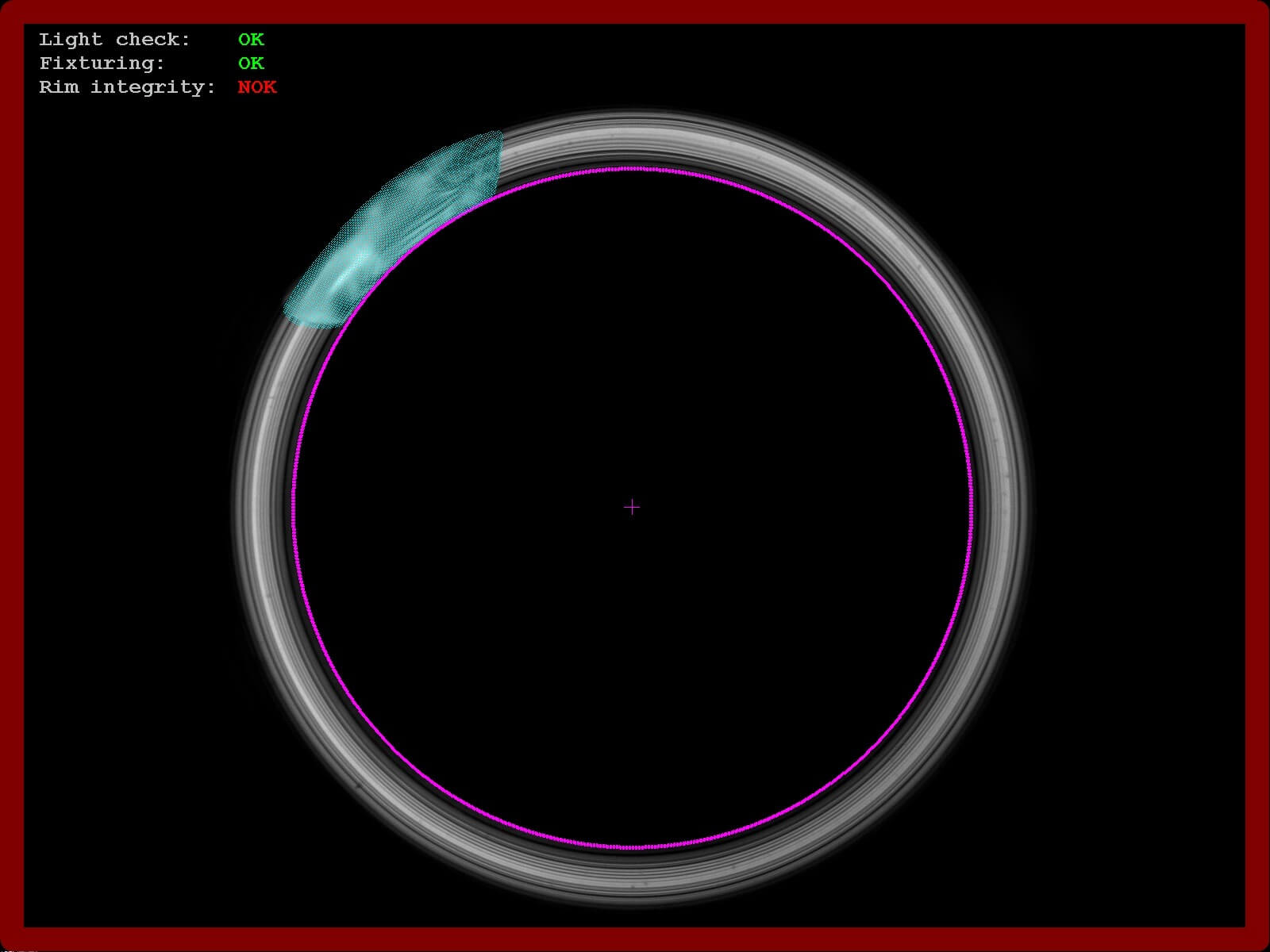

Inline detection of chips and cracks

Injection pen manufacturers require advanced inspection systems to safeguard both their products and patients, while complying with strict safety standards and regulatory requirements.

However, injection pen cartridges are fragile, and the multiple handling steps during production increase the risk of chips and cracks in the glass.

Detecting defects early in the process is crucial, as a broken cartridge in the filling machine, for example, can lead to costly and lengthy production downtime.

Today, the inspection task is often performed as a final quality control with advanced and expensive inspection systems that lift and rotate the cartridges, but this approach misses the opportunity to catch defects early.

However, the challenge with inline inspection is that the vision system must be adaptable and compact to fit into the existing production line, and the cartridges need to be inspected from the edge at the open end. Detecting very small chips and cracks in glass by inspecting from the edge is a difficult task, partly because the defects must be identified among various elements that interfere with the image but are not defects, such as silicone residues.

The task can only be solved with AI, and JLI vision has developed a validated AI-based vision system that can detect chips and cracks with +99% accuracy.

Benefits of the chips and cracks inspection system:

- Defects can be caught early since quality control can be placed in multiple places on the production line.

- Small footprint enables installation on existing production lines.

- Validated AI-based vision system.

A validated AI-based vision system

Finding chips and cracks in injection pen cartridges from the open end is an inspection task so complex that only AI can handle it.

AI identifies segments with potential defects, while a traditional machine vision algorithm determines whether these segments are indeed defects. The challenge of using this process in the medical industry is, of course, that AI solutions are typically difficult to validate.

However, the chips & cracks system is built in a way that makes it possible to validate.

This involves, among other things:

- Extensive pre-processing of the images, which are normalised to resemble the training set

- Continuous monitoring to ensure that the images are within the scope of what it has been trained on

- Strict requirements for the process of annotating training images

- Extensive documentation and control of training and testing

The Chips & Cracks Vision System has been validated by one of our customers as one of the very few AI-based vision systems in the world.

.jpeg?width=1923&height=1078&name=CC_display%20%E2%80%93%20redigeret%20(1).jpeg)

System specifications

The injection pen cartridge inspection system is built on premium hardware and software fitted to your needs.

- Crack detection rate: +99%

- Chip detection rate: +99,9%

- Speed: 1200 cartridges per minute

- Cartridge size: Ø6 - 10mm

- Operating temperatures: 5-45 Celcius

- Humidity: 20-80% non-condensing

- All hardware designed for 24/7 usage

- Interface: Digital I/O, EthernetIP

- LDAP /Secure LDAP for user administration

- 23” touch screen

- Small footprint. Can be integrated into filling line or packaging line

Book a meeting to learn more:

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting