Machine Vision for Inline Tube Inspection

Inline tube inspection with high speed and sensitivity

Vision systems used for inspection of pharmaceutical and technical glass production. Designed and developed to meet high demands for speed and sensitivity.

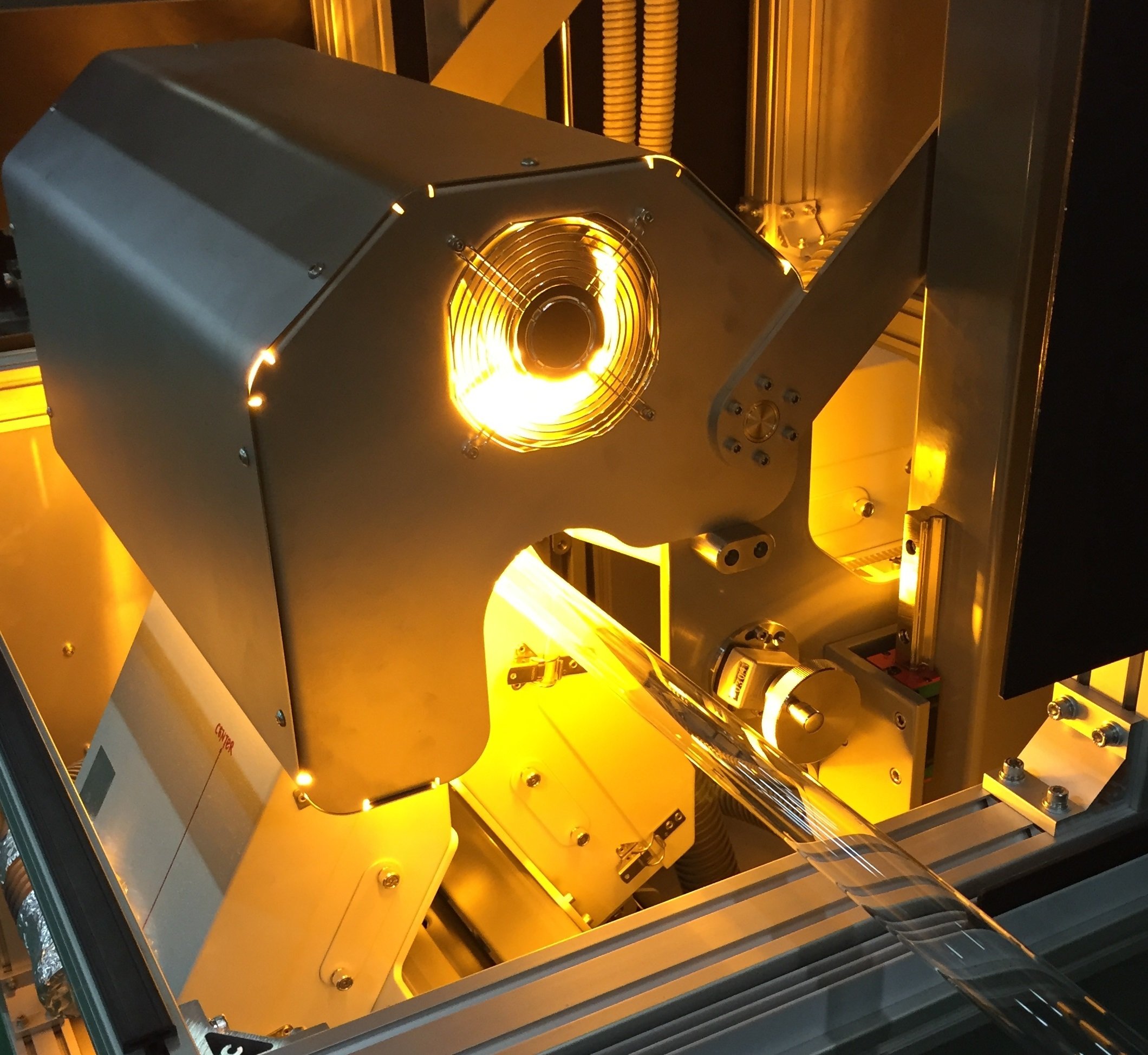

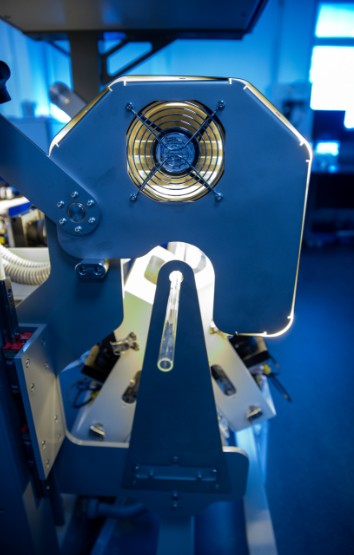

JLI vision’s Tube Inspection Systems in the SK-3000 series are compact stand-alone units.

The SK-3020, SK-4020, and SK-3020D are fourth generation and have been developed to meet high demands for speed and sensitivity.

All vision systems can be used for technical and/or pharmaceutical glass production. They employ a number of high-resolution line scan cameras and stabilized long-life light sources.

By pneumatic pressure, the illumination unit can lift up to provide free access at line start-up. You don't need to do any tube handling. The tube runs unrestrained through the inspection module.

Glass tubes are inspected for stones, knots, and airlines. Through a touch panel user interface, the sensitivity can be set and defect patterns can be selected.

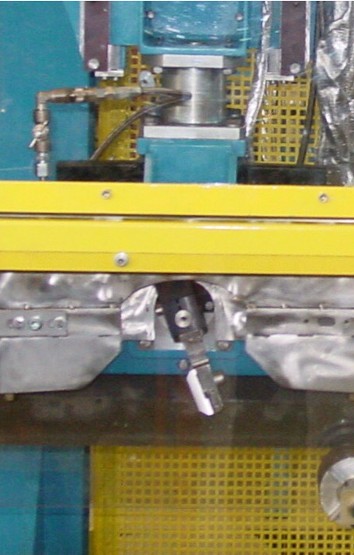

When defects exceed a selected tolerance, a signal is timed and sent to the reject mechanism.

The vision system can also be delivered as an off-line sampling unit.

Why choose the JLI Inline tube inspection system?

- High speed inspection

- 21 CFR PART 11 compliant

- Compact and portable stand alone unit for in-line and off-line inspection

- Fast changeover between different tube types

- Optional detection of cord and turn-cord (V-cord)

- Clever Cutting available for significant waste reduction

Example systems in

Glass Inspection:

Designed and developed to meet high demands for speed and sensitivity.

Reduce waste by up to 40%

The system will continuously measure and inspect tableware as the glasses pass on a conveyor.

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)