Oil spills on production lines are a common issue in many industries, and so far, there hasn't been an efficient and cost-effective way to detect these oil droplets. Hyperspectral detection methods exist, but they are quite expensive.

Through research on how different oil types interact with light of various wavelengths, JLI has now developed a method by using spectral imaging to detect oil droplets that is reliable and affordable.

We examined how different oil types respond to light at various wavelengths. The goal was to determine if the oil absorbed light at specific wavelengths. making it possible to use these properties in a vision system setup.

The problem with oil droplets is that they are transparent, making it difficult to detect them with a traditional vision system. Normally, you would try to detect a reflection in the surface of the oil, but this requires a specific angle of the lighting, which is challenging as the placement of the oil droplets is essentially unpredictable.

Four oil types examined

To solve this problem, we investigated how different oil types react to light with various wavelengths. We’ve examined four oil types - paraffin oil, silicone oil, mineral oil, and synthetic base oil (C11) - and subjected them to radiation with wavelengths ranging from 200 to 1000 nm.

The idea was to see if the oil absorbed light with specific wavelengths, making it possible to use these properties in a vision system setup.

We found that paraffin oil, mineral oil, and C11 exhibited significant absorption in the range of 200-450 nm (UV light), while silicone oil did not.

With this knowledge, we were then able to create a vision system that can efficiently detect oil droplets with a UV-sensitive camera. By radiating UV light at a wavelength of 365 nm onto the surface to be inspected and placing a filter in front of the camera that only allows this UV light to pass, we can see how the otherwise invisible oil droplets now appear as dark spots. This technique also has the advantage that the oil stains appear dark regardless of the angle from which the light hits them.

The image below illustrates how oil droplets are invisible when viewed using visible light (left side), whereas they stand out clearly in UV light (right side).

Fluorescence also a useful technique

In the search for effective methods to detect oil spills, we have also explored fluorescence as a detection technique.

Here we take advantage of the fact that some substances absorb one color of light (in this case, short-wavelength UV light) and, in exchange, emit a different, less energetic color of light (in this case, visible light). This process is called fluorescence.

As the emitted light is visible light, we can use a standard camera in the vision system, making it a cheaper solution. We only need to place a filter in front of the camera to filter out UV light, allowing only visible light to pass through.

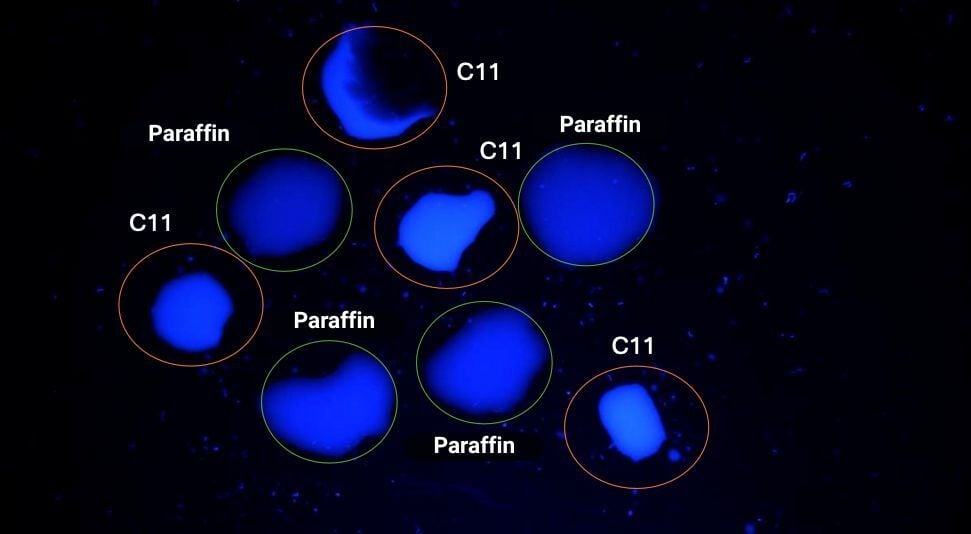

We found that both paraffin oil and C11 could be detected by using fluorescence.

The drawback of using fluorescence is that it requires the scene of detection to be completely dark, as normal light will drown out the fluorescence. This is, of course, a limitation that will make this technique less useful on many production lines.

The drawback of using fluorescence is that it requires the scene of detection to be completely dark, as normal light will drown out the fluorescence. This is, of course, a limitation that will make this technique less useful on many production lines.

Therefore, depending on the type of oil you are trying to detect, using a vision system based on UV light may be a robust and cost-effective method for detecting oil spills. Whether to use absorption or fluorescence will depend on the demands of your production environment.

%20Stor.jpeg)