Traditional vision systems have long been the backbone of automated inspection in manufacturing. But there’s a new technology in town that holds great potential when microseconds matter or when motion blur and data overload become real constraints.

It’s called event-based vision, and in this article, we’ll explain the concept of event-based cameras and look into how they can enhance industrial quality control and predictive maintenance.

What is event-based vision?

Unlike traditional cameras that capture full frames at fixed intervals (e.g., 30 or 60 frames per second), event-based cameras operate asynchronously. Each pixel on the sensor independently monitors for changes in light intensity and generates an event when a change in light intensity is detected.

This model mimics how the human eye works, only reacting to change, not static scenes. The result is a system that provides high temporal resolution, high dynamic range, low latency, and significantly reduced data volumes.

Comparison: Traditional vs. event-based cameras

|

Feature |

Traditional camera |

Event-based camera |

|

Capture mode |

Frame-based (e.g., 30 fps) |

Event-driven, per-pixel |

|

Latency |

Milliseconds |

Microseconds |

|

Data volume |

High (full images per frame) |

Low (only pixels that change) |

|

Motion blur |

Common at high speeds |

None |

|

Dynamic range |

Standard |

High (suited for variable lighting conditions) |

|

Power consumption |

Higher |

Lower |

The key advantages of event-based cameras

As the above comparison shows, event-based vision has some clear advantages in demanding inspection environments. Its key advantage lies in its asynchronous, pixel-level response to visual changes, allowing systems to detect motion and anomalies in real time without the overhead of processing entire image frames.

This drastically reduces latency, down to microseconds, making it ideal for applications like high-speed rejection or robotic feedback loops.

Additionally, the technology’s inherent high dynamic range enables reliable operation in environments with challenging lighting conditions, such as glossy materials or outdoor production lines. An event-based camera can handle scenes where the brightest point is up to 10 million times brighter than the darkest point, and still capture details. For a conventional camera, the limit would be around 1000 times brighter than the darkest point.

Because it only captures changing pixels, event-based vision also reduces data loads and energy consumption, streamlining both hardware and processing requirements.

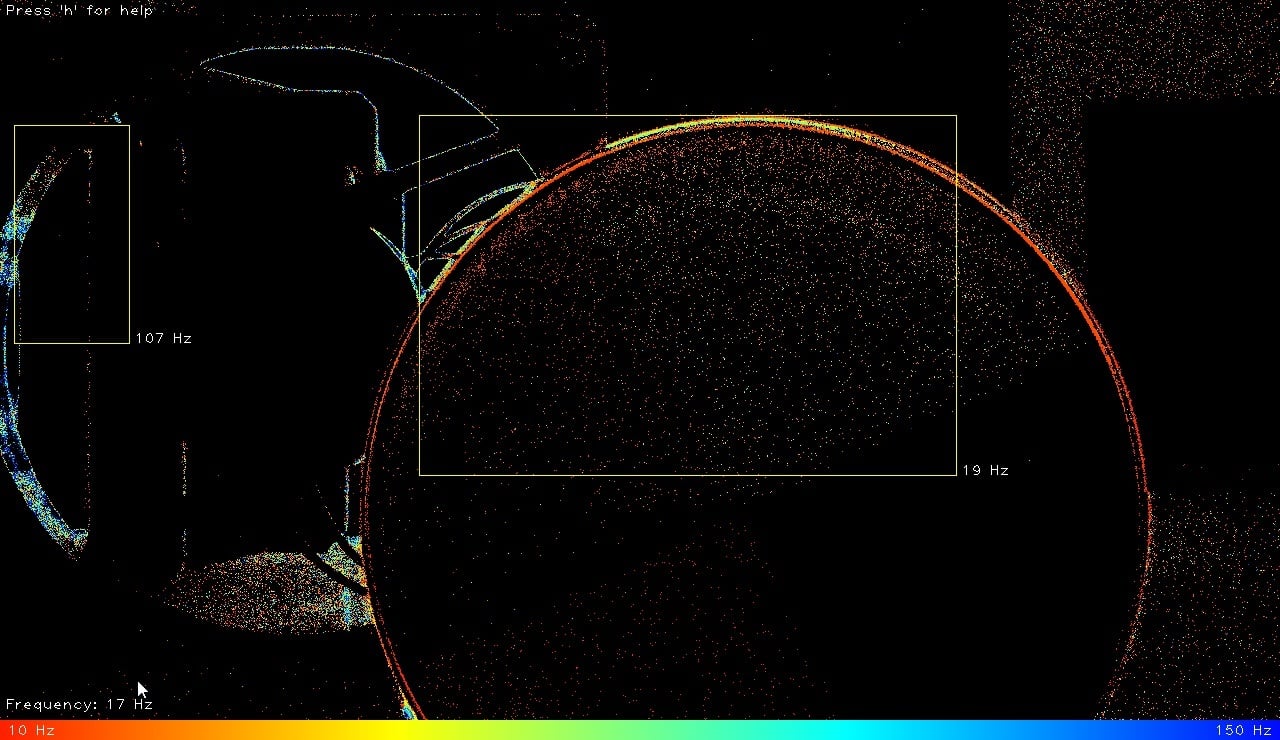

Vibration detection with event-based vision technology.

Vibration detection with event-based vision technology.

Challenges with event-based cameras

However, this innovation comes with its own engineering hurdles. The data generated by event-based cameras differs fundamentally from conventional image formats, which means existing vision libraries and tools may not be compatible without adaptation.

Engineers need to rethink how they structure their algorithms, focusing more on event stream processing than frame analysis. The noise in raw event data also requires sophisticated filtering to prevent false positives, especially in environments with background flicker or micro-movements. Since these systems don’t output traditional images, diagnostics and training will also require a shift in mindset: from visually inspecting images to interpreting live event streams.

And of course, there is a price tag to consider. In general, event-based cameras are considerably more expensive than traditional cameras, which in itself might limit the number of attractive use cases. Also, it’s worth noting that event-based vision isn’t well-suited for static scenes.

Examples of event-based vision applications

Label inspection in pharmaceutical packaging

In pharmaceutical production, label integrity is not just about branding, it's a regulatory requirement. At line speeds reaching over 1,000 units per minute, traditional vision systems can struggle with motion blur and lighting inconsistencies, especially on reflective foil or transparent containers.

An event-based vision system captures every slight deviation in real-time. If a label is misaligned by even a few millimeters, has a missing print segment, or is creased, the system flags it immediately.

With microsecond-level response times, it can synchronize precisely with reject mechanisms, preventing faulty packages from reaching downstream processes or distribution.

This is particularly valuable in serialization processes, where traceability and clarity of printed codes are critical for compliance.

Predictive maintenance on rotating machinery

Rotating machinery like motors, spindles, and rollers is a critical point of failure in many production lines. Traditionally, vibration sensors or acoustic monitors are used to track mechanical health, but these systems can miss early-stage anomalies or require contact-based installations.

An event-based camera can monitor the edge or surface of a rotating component and detect subtle oscillations or irregularities in movement patterns. These minor shifts can trigger predictive alerts before performance degrades or failure occurs.

High-speed pill counting and verification

In pharmaceutical manufacturing, accuracy in pill counting is essential. In high-speed bottling lines, pills or capsules are typically dispensed into containers at rates too fast for traditional cameras to reliably track.

Event-based cameras excel here because they don't waste cycles processing static frames. Instead, they detect the motion of each pill as it drops through the feed chute, capturing high-speed motion without blur. This enables accurate, real-time pill counting—even when pills are irregularly shaped, translucent, or exhibit varied surface finishes.

Moreover, the system can verify not just the count, but also detect unexpected shapes, sizes, or breakages in-flight, catching defects before the container is sealed.

Emerging technology, new solutions

Event-based vision isn’t going to replace traditional vision systems, but it excels at some tasks where the traditional methods tend to fall short. When inspection speed, dynamic lighting, or motion fidelity become constraints, event-based vision could be a robust solution to consider.

So, if you’re facing inspection challenges where conventional cameras are hitting their limits, it might be time to explore this emerging technology.

%20Stor.jpeg)