First of all, the machine vision industry has witnessed extensive developments and innovative upgrades ever since its emergence. Important factors, such as an increasing need for quality products and productivity, are influencing the growth in the global machine vision market.

What new trends are worth keeping an eye on and could possibly change the way that machine vision technology is deployed in the future? At JLI we are intensely following four areas. They have all played a major role at JLI in 2019 and will also have a prominent role in 2020 as we focus even more on important issues such as: the ease of use of systems and gaining greater flexibility in changing the setup of systems for new products. Regarding ease of use, machine vision systems can often be complex from the user’s perspective, JLI will focus on making systems easier to deploy. We will also focus on providing systems with a higher flexibility, especially aimed at improving the ability to re-configure systems regularly if used on small batch sizes.

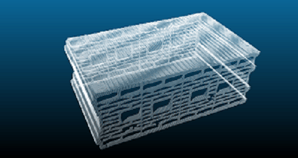

3D imaging

3D imaging has been a steadily growing technology within machine vision. The availability of sensors have exploded in the past few years and components are becoming more sophisticated and targeted for specific application such as robot guidance, high speed scanning of volumes and precise 3D modelling. Most applications require accurate and reliable 3D images. There has been proliferation of 3D imaging technology, like triangulation, stereo vision, time of flight and structured light. Structured light with stereo vision has begun to penetrate the 3D segment and shows great promise. At JLI we focus on providing advanced systems for inline 3D gauging of moving objects. In 2020 we expect to release the first version of our inline 3D portal capable of comparing real world moving objects with their original CAD model.

3D imaging has been a steadily growing technology within machine vision. The availability of sensors have exploded in the past few years and components are becoming more sophisticated and targeted for specific application such as robot guidance, high speed scanning of volumes and precise 3D modelling. Most applications require accurate and reliable 3D images. There has been proliferation of 3D imaging technology, like triangulation, stereo vision, time of flight and structured light. Structured light with stereo vision has begun to penetrate the 3D segment and shows great promise. At JLI we focus on providing advanced systems for inline 3D gauging of moving objects. In 2020 we expect to release the first version of our inline 3D portal capable of comparing real world moving objects with their original CAD model.

Machine learning

Machine learning is indeed revolutionizing the role of machine vision in industrial automation. Using machine learning helps enable machine vision systems to adapt to variations in manufacturing. Machine learning also promises to improve operational efficiencies, accelerating inspection processes, and increasing productivity in applications that were not cost-effective to strive for in the past. Machine learning solves vision applications difficult to program with rule-based algorithms, handling difficult surfaces textures and variations in part appearance. JLI has successfully implemented systems incorporating machine learning in 2019 that effectively handled complex inspection and classification tasks in more dynamic materials such as wood, steel and glass. We expect machine learning techniques to rapidly become more advanced in 2020 and assist us in solving even more complex applications.

Machine learning is indeed revolutionizing the role of machine vision in industrial automation. Using machine learning helps enable machine vision systems to adapt to variations in manufacturing. Machine learning also promises to improve operational efficiencies, accelerating inspection processes, and increasing productivity in applications that were not cost-effective to strive for in the past. Machine learning solves vision applications difficult to program with rule-based algorithms, handling difficult surfaces textures and variations in part appearance. JLI has successfully implemented systems incorporating machine learning in 2019 that effectively handled complex inspection and classification tasks in more dynamic materials such as wood, steel and glass. We expect machine learning techniques to rapidly become more advanced in 2020 and assist us in solving even more complex applications.

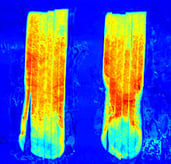

Hyperspectral

Much of the industrial use of hyperspectral imaging is currently focused on modern applications such as food quality, medical diagnosis/image guided surgery and waste recycling. Particularly waste recycling is gaining focus in these global warming times. Recycling and sorting systems will continue to evolve and become more accurate and easier to implement. Further camera developments will - perhaps aided by machine learning - be a key to rolling out the technology in more applications and making it more accessible. In 2019 JLI successfully solved a difficult task detecting transparent silicone after being dispensed and we will keep looking for more industrial applications.

Much of the industrial use of hyperspectral imaging is currently focused on modern applications such as food quality, medical diagnosis/image guided surgery and waste recycling. Particularly waste recycling is gaining focus in these global warming times. Recycling and sorting systems will continue to evolve and become more accurate and easier to implement. Further camera developments will - perhaps aided by machine learning - be a key to rolling out the technology in more applications and making it more accessible. In 2019 JLI successfully solved a difficult task detecting transparent silicone after being dispensed and we will keep looking for more industrial applications.

Embedded vision

Embedded vision is continuing to be broadly adopted. Embedded systems are compact systems constituting miniaturized PC's or processing board and powerful board level cameras designed for a specific application. Systems are gaining traction because of their characteristics, such as light weight, small size, low cost, low energy consumption, and user friendliness. Embedded systems find applications in autonomous mobile robots, driver assistance systems, industrial drones, biometrics, medical imaging, and space imaging. For machine vision, the use of low-level embedded systems in specific single-purpose applications likely is not practical as programming an embedded vision device remains more of a development than an integration task, hence they are aimed at higher volume applications. A broader use case for embedded vision might be in the implementation of cameras with “pre-programmed” embedded image processing applications—particularly machine learning networks.

Embedded vision is continuing to be broadly adopted. Embedded systems are compact systems constituting miniaturized PC's or processing board and powerful board level cameras designed for a specific application. Systems are gaining traction because of their characteristics, such as light weight, small size, low cost, low energy consumption, and user friendliness. Embedded systems find applications in autonomous mobile robots, driver assistance systems, industrial drones, biometrics, medical imaging, and space imaging. For machine vision, the use of low-level embedded systems in specific single-purpose applications likely is not practical as programming an embedded vision device remains more of a development than an integration task, hence they are aimed at higher volume applications. A broader use case for embedded vision might be in the implementation of cameras with “pre-programmed” embedded image processing applications—particularly machine learning networks.

Please bear in mind that not all machine vision applications call for implementation of the latest and new trending components/technologies. Often new components/technologies act as just another tool in the belt, that together with traditional machine vision will help solve your application.

At JLI we try to maintain a solid perspective with respect to new components/technologies that continue to enable more productive manufacturing for our customers.

%20Stor.jpeg)