JLI develops many vision systems to customers specifications and for special applications. We have a large staff of development engineers who have been with JLI for decades. We have 300 man-years combined experience in developing advanced vision systems. They are always “First in the world”. If a solution exists in the market, JLI will recommend this rather than developing our own solution. Our systems are installed worldwide and serviced from our home base in Copenhagen.

Essential steps

When the customers contact JLI we go through a number of questions to find out if it is feasible to propose a solution with vision technology. Here are some of the first questions:

- Type of inspection - on line off line

- Descriptions of parts and the defects that must be detected

- Inspection speed

- Environment

- Consequences of false reject/accept

- And much more

We often receive images of the parts and of defects. When it looks possible, we ask for samples.

These must include marginal faults. Marginal faults are the faults that may be accepted or may be rejected. These borderline defects are necessary to determine the sensitivity and thereby the cost of a system.

If it is not practical to send samples, we can sometimes work on descriptions and images of the parts and their expected defects.

With this information we can determine which category the system is likely to fall under:

- Off the shelf systems

- Known projects

- Development projects

Off the shelf systems

Off the shelf systems are vision systems we have developed into products. There are no unknowns, and we can easily calculate a price for the equipment and a price for installation and commissioning.

There may be variations to the specifications but as long as these are within the general capabilities of the systems, we can accommodate this, typically without extra cost.

Known projects

These are projects we have done before, maybe for other applications or in a different industry.

JLI can normally, on the basis of a thorough sample set, find a solution and calculate a price and delivery time.

Development projects

These are the projects where we are expanding the capabilities of the techniques used in the system. It could be the need to inspect faster, with greater resolution or accuracy, doing it in colour, 3D or using Machine Learning.

Many projects have been developed by the engineers, and this is why we can keep expanding our knowhow and technology. Most of our solutions are “first in the world” where nobody else have developed a similar solution.

In order to reduce the risk in these projects and get an understanding of the capabilities and limitations, we normally start with a paid preliminary investigation. This is part of the work towards a fully installed and functioning system and it is not an extra cost. The idea of the preliminary investigation is to make sure that techniques can be developed to meet the required specifications.

If it turns out that the solution will be too complicated or to costly, it is good to know after having spend a small amount of time, rather than cancelling a project at a later state.

Starting a development project

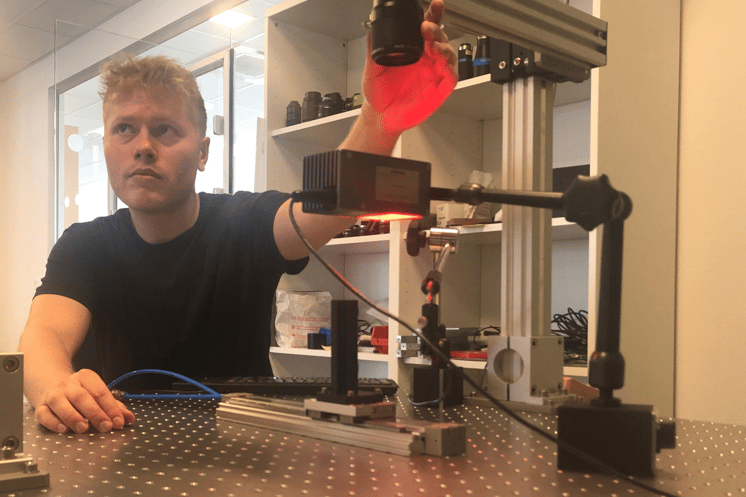

A team is formed for the duration of the project. It consists of minimum two engineers who will draw on the expertise of the whole company. They are responsible for everything related to the project, buying components, designing, testing, installation and commissioning. It is a key feature in JLI, that the project team takes all the phases from ideas to commissioning. We do not have special company functions such as purchasers, developers or field engineers. The project engineers will also be responsible for commissioning. This has great benefit for the customers and for JLI, as the last adaptation will be done by the engineers who have the full understanding of the system.

JLI always takes full responsibility for a satisfactory solution. JLI are the experts in vision technology, and we cannot expect our customers to see the full implication of getting a vision system on line in the production. JLI have done more than a thousand installations and have a lot of hands-on experience in making things work.

We normally say that we need four holes drilled in the floor and 230 V – then we take care of the rest.

JLI operates with a “No cure no pay” clause. This basically means that if the system does not meet the specifications or does not give benefits to our customers, we will take back the equipment and repay all money paid to JLI. JLI does not cover consequential cost such as the time the customer has spent on the project or cost of constructions made-up for the installation.

On average JLI have about 30 systems under development at any given time.

Having such a large number of developments ongoing keep us sharp on new methods, components and the new software developed by the JLI.

%20Stor.jpeg)