Rapid prototyping is an excellent way to test concepts.

Can this inspection or gauging be done? What kind of accuracy can be achieved, and how fast can it run?

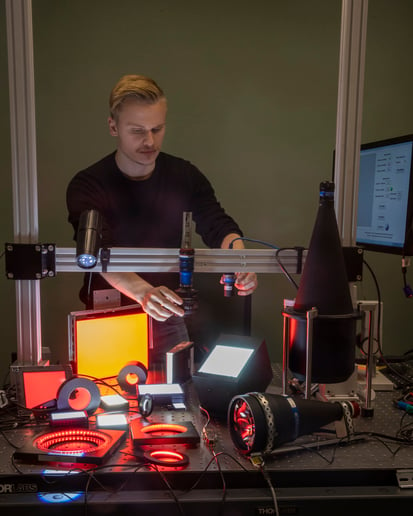

To do rapid prototyping you need a good laboratory with all sort of illumination units, optics, cameras and computers. It is also essential to have mechanical handling equipment from robots to conveyors or indexing tables. We have 3D printing in house and can make special mechanics to hold cameras and samples from the customer.

Most important is our large staff of experienced engineers. Many of them have been with JLI for 25 years or more, and they have experience from many installations in all kind of industries. At JLI we work in project teams. When we have a request from a customer to quickly evaluate a concept, we engage the engineers with the right experience required for the prototyping job.

Accumulated vision knowledge among the staff we have today is about 400 man-years. So much time have we worked together developing and commissioning advanced vision systems. Our installations are spread worldwide and we probably have more than 1.000 systems in operation.

We aim at always having spare capacity so we can take on new investigations with very short notice. We always need to have a little more engineers than required for the projects at hand. This is a good strategy for putting extra manpower into unforeseen problems in the projects, or to help our customers with rapid prototyping.

Our customers use us when they want to investigate a concept or are in desperate need for a solution to a problem that suddenly emerged.

Here are a couple of examples for rapid prototyping we did for our customers:

A plastics manufacturer in Jutland suddenly had a problem with a large number of parts where a small percentage did not meet specifications. To manually sort through the many hundred thousand parts would demand many operators and a lot of time.

Sample parts were sent by taxi to JLI in Copenhagen and we reported back the next day that we were able to make a system. Two engineers were put on the job and 32 days later we delivered a fully functioning system.

A funny part of this story is on the commercial side. There was no time for the purchasing procedures, so JLI worked without an order. After the system was in operation, we made the proposal – which the customer accepted – and then we could invoice the system.

This shows how fast we can respond and how flexible we can be, also on the commercial side.

Another customer had a problem that required a quick solution. We received samples, build a mockup og the handling equipment and programmed a smart camera to demonstrate the inspection. It was spot on, and the customer asked to have the system installed on line at once. It was all done within one week.

We expect a follow up where we can finalize the equipment design and replace the ad-hoc solutions with professionally engineered parts.

JLI is always ready to accept a challenge and put all our experience and knowhow into a solution. Ask us – we may be able to find a fast solution.

%20Stor.jpeg)