Machine vision for Rail Surface Inspection

Inspection of fast-moving and red-hot rails

JLI vision has developed a rail monitoring system that operates on a continuous 24h basis and is installed before the cooling bed.

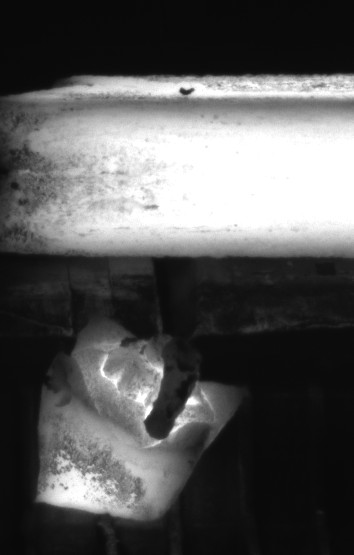

The sections pass through a ring holding 7 adjustable cameras and flood lights. At this point, the rail is red hot and moving at speeds up to 4 meters a second. The purpose is to facilitate surface inspection and read stamped characters.

Using optical filtering images are enhanced making the rail visually appear as cold.

As the rail enters the camera ring, images from up to 7 cameras are recorded. The system saves images of entire rails. Approximately 2000 images are stored for each rail, these are subsequently compressed and made available to the operators.

Case: Inspection for British Steel

"Since the very beginning of rail manufacturing at Scunthorpe Rail and Section Mill back in 2006, we have operated the JLI vision system as a tool to inspect and provide rapid feedback to the rolling mill team regarding surface quality. The system is highly intuitive, easy to operate and it is easy to understand its output – so training new operators is also quick. Other vision systems we have experience with - produce a flattened image which is difficult to orientate and interpret. Speed is essential to minimise defects.

It has become an essential tool for controlling surface quality and has become fully integrated into our quality management system. It is so important that on the rare occasions we have a fault with the system, we stop rolling...because rolling without it is rolling blindfolded.

Over the years, we have had upgrades to the cameras and lighting, ensuring that the vision system keeps up with advancing technology. We are very satisfied with the performance of this tool and it has ensured British Steel maintains its reputation for exceptional quality on both rail and sections."

- Andrew J Wilson, Technology Manager SRSM, British Steel.

Why choose the JLI Rail Surface Inspection System?

- Stand-alone unit

- Inspection performed at the hot-end, < 900o C

- Replaces physical sample inspection

- 360 inspection - no turn mechanism needed

- Instant detection of errors down to 1 mm

- Automatic detection of reoccurring defects

- High-speed inspection

- Can be configured for rails and sections

- Internet connectivity

- Quick data retrieval of the previous production

- Stores images for documentation

Example systems in

Steel Inspection:

Book a meeting to learn more

.png)

Send me an email at hb@jlivision.com

or book a meeting, and let's find out how we can help you.

Glass Inspection

Glass Inspection

.svg) Medical Device Inspection

Medical Device Inspection

Steel Inspection

Steel Inspection

.svg) Wood Inspection

Wood Inspection

.svg) Building Industries

Building Industries

Packaging Inspection

Packaging Inspection

Plastic Inspection

Plastic Inspection

Standard Vision Systems

Standard Vision Systems

.svg) Customized Vision Systems

Customized Vision Systems

3D / Robotics

3D / Robotics

.svg) Surface Inspection

Surface Inspection

Color Inspection

Color Inspection

Consulting

Consulting

.png)

.jpg?width=1440&height=696&name=Group%2050%20(1).jpg)