Is a color a color? Or isn’t it?

We are surrounded by colors every day, and we don’t think about what color the color really has….we just enjoy the color as we see it….

The human eye sees a color in accordance to how the different wavelengths are recognized and interpreted by the brain.

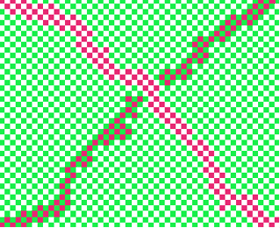

This differs from human to human, and that’s why colors very often are discussed among people, and where two people can have a completely different perception of what color a painting or a dress seems to have. Ex. At the left it looks like there are three colors – green, pink and dark red. But if you zoom in on the image, you would surprisingly see that the pink and ‘dark red’ are the same color – it just looks different because of the different neighbor colors (for the pink it is white color, and for the ‘dark red’ it is the green color).

How colors are perceived can also have a cultural background. In some countries they have plenty of words to describe a specific color, as in others there are only few words. Ex. There are many more words for the color blue in Russia than in Europe.

In machine vision we are struggling with some of the same problems - how to decide what color a color has? It is very hard to measure the correct color.... it depends on how you do it.

There are many things that have influence on the color ‘seen’ by a camera, and the challenge to present the ‘same’ color to an operator, that has his perception of that specific color. We need a setup independent of the human perception, that can be calibrated and work precisely independent of time.

To overcome some of these challenges we need to look closer at ´how to define a specific color’.

A color is a reflection of a specific spectrum of wavelengths that is not absorbed by the material the lights hits. The light is of importance, the materiel the light travels along or through and the disturbance from filters, lenses etc.

To try to define a color, you need to have a specific light source and a normed color table to calibrate your system against. There are different suppliers of these standard color tables. The normed color tables are sensitive to sunlight, and therefore has to be stored in darkness – to be sure, the color will give the same result, next time the calibration is done. To match the measured color against the standard color space you need to do several calibrations.

The cameras are mostly the same, but the light sources are very different, that’s why you need to calibrate every time, you are changing your light source. There are other disturbances like the lens and the coating on the lens. These can be calibrated with some effort, but is necessary for a precise measurement.

The control and calibration of the light source can also be necessary to get the right measurement.

There are special equipment’s for measuring the spectrum of a light source. Often will the datasheet for a specific light source, show which spectrum the light will have. A wavelength can miss in a light source, which means that you won’t be able to measure the color at that specific wavelength – and you will not be able to calibrate your system

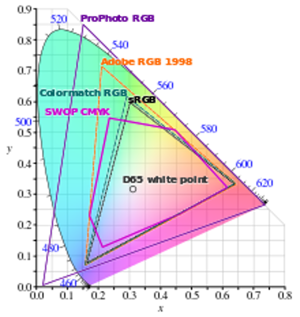

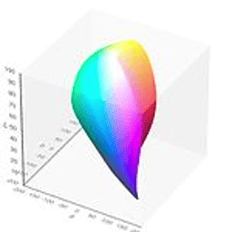

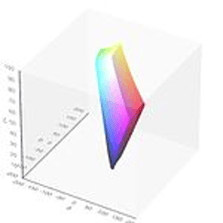

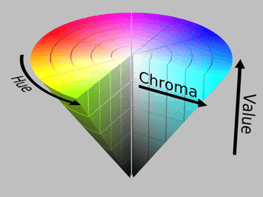

There are different standard color spaces (RGB, HSV, CMYK, CIE lab etc.) that can be used to describe the colors. The different color spaces are used accordingly to

There are different standard color spaces (RGB, HSV, CMYK, CIE lab etc.) that can be used to describe the colors. The different color spaces are used accordingly to

the application, and the needed color variances.

The presentation of a color can be limited to the color range for a specific hardware, and therefore no need to use a more detailed / broader color space.

These are often 2 or 3 dimensional representations, where a color is represented by a coordinate x,y,

JLI has deep knowledge about colors, light and the different aspects of how to measure the color correct. JLI has developed a special series of calibrations tools that gives us a very precise color detection. These tools have helped international customers to have full control of their colored products, at any time in the production line – from supplier to end product.

JLI has invested time and resources to gain that deep knowledge, which will be used in new projects around the world.

A color is not just a color…..

%20Stor.jpeg)